Installation notes of Robots bearing-HONB

- 2020/5/9 17:25:03

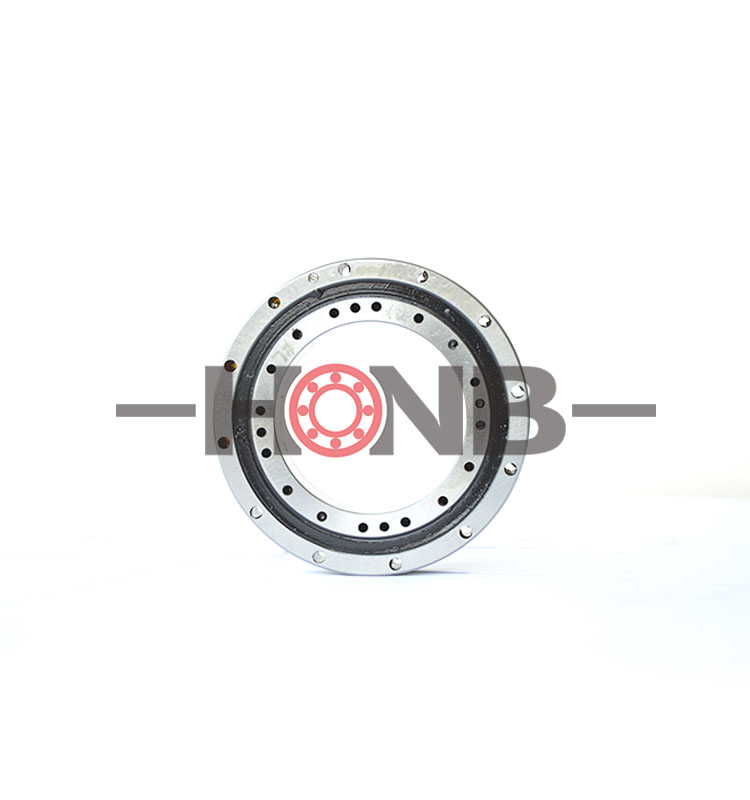

Installation notes of Robots bearing-HONB

The main axis, the bearing set or other parts must be fully cleaned before installment, no greasy dirt or the impurity, and make sure the bearings have no burr or the fragments. (Be sure that the bearing inner diameter and outer diameter of the bearing meet the requirements, shaft and bearing bore diameter tolerances meet the requirements.

When you tighten the screws, fixing bolt locking from non-full locking to full locking was divided into 3~4 stages, according to criss-cross method repeated locking . Any questions, please feel free to contact us.

Before bearings are finished, the bearings preload has been adjusted and greased by professional staff, no one is permitted to disassemble the bearing parts or clean inside of bearings without consulting us. Do not disassemble or clean the bearings internal parts before installation without our permission). Please feel free to contact our after-sales staff if they are not good after bearing received.

Bearing operating temperature-(is)20 ℃ ~+ 80 ℃, if bearing operating conditions beyond this range, please contact with our technical staff.

Refer to the material of parts which conjunct with bearings; you can use aluminum, cast iron.

If the bearing size could not be found in the sheet, please contact our technical staff.