Application of Crossed Roller Bearings in Industrial Robots

- 2019/9/7 17:37:25

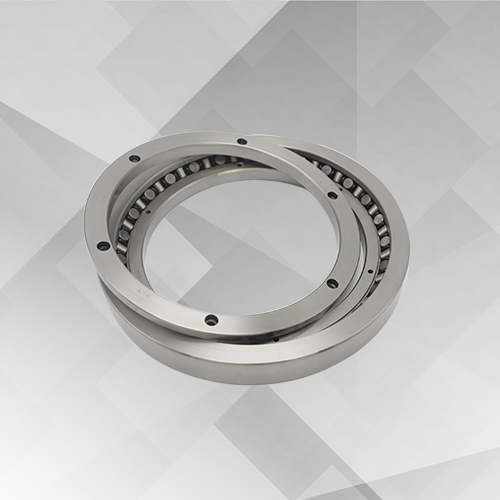

The crossed roller bearing is a special type of bearing with inner ring splitting and outer ring rotation. Since the divided inner ring or outer ring is fixed to the cross roller collar after being loaded into the roller and the spacer, to prevent separation from each other, the operation is simple when the cross roller collar is installed. Because the crossed roller bearing is a two-part structure of the inner ring outer ring, the bearing clearance can be adjusted, and even if the preload is applied, the rotation can be performed with high precision. Because of the special structure, it is generally used for the joint bearing of the industrial robot. Today, let's talk to you about cross-roller bearings. Let's take a look at it!

There are two main types of bearings for industrial robots: equal-section thin-walled bearings and crossed-roller bearings. The bearing of industrial robot is one of its key components. It is suitable for joint parts or rotating parts of industrial robots, rotary table of machining center, robot rotating part, precision rotary table, medical instruments, measuring instruments, IC manufacturing equipment, etc. Wide range of uses.

Advantages of crossed roller bearings for robots:

1, with excellent rotation accuracy

The internal structure of the crossed roller bearing is arranged at 90° perpendicular to each other by rollers. The spacers or spacers are arranged between the rollers to prevent the rollers from tilting or friction between the rollers, thus effectively preventing the rotational torque. increase. In addition, the contact phenomenon or the locking phenomenon of the roller does not occur; at the same time, since the inner and outer rings are divided structures, the gap can be adjusted, and even if the preload is applied, a high-precision rotary motion can be obtained.

2, the operation is simplified

The outer ring or inner ring that is divided into two parts is fixed together after the roller and the retainer are loaded, so the operation is very simple to install.

3. Withstand large axial and radial loads

Because the rollers are vertically aligned with each other through the spacers on the 90° V-groove rolling surface, this design allows the crossed roller bearings to withstand large radial loads, axial loads and moment loads. Directional load.

4, greatly save installation space

The size of the inner and outer rings of the crossed roller bearing is miniaturized to a small extent. In particular, the ultra-thin structure is a small size close to the limit and has high rigidity, so it is suitable for the rotary work of the joint portion or the rotating portion of the industrial robot and the machining center. Wide range of applications such as table, robot rotating parts, precision rotary table, medical instruments, measuring instruments, and IC manufacturing equipment.

The above is the whole of the advantages of crossed roller bearings for industrial robots. In general, in industrial robot bearings, cross-roller bearings are a very suitable type of bearing, which makes the joints of industrial robots more flexible, and it has Excellent rotation accuracy, very simple in operation, bearings can carry large axial and radial loads, and can greatly save installation space. Today's sharing is these, if you have any questions, you can do it. Message or telephone consultation, Hongyuan Bearing welcomes your inquiry and order.