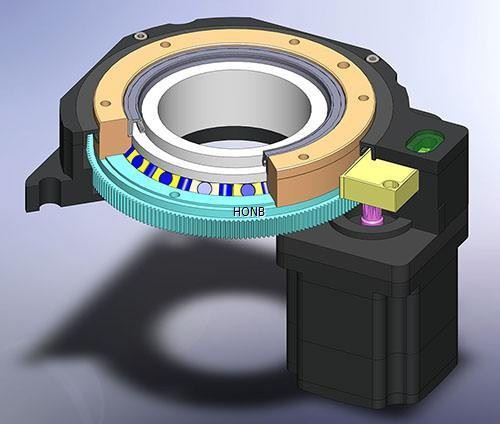

Application case of cross roller bearing for hollow rotating platform

- 2019/3/15 17:41:02

Hollow rotating platform is a revolutionary product, which is used in a variety of rotating sports occasions. It can replace DD motor and cam divider. Set high efficiency, high precision, high rigidity, high cost performance in one. It is a revolutionary product in rotating mechanism. The balance between the two is achieved, the repeated positioning accuracy is ≤ 5 seconds, the motor is easy to configure, and the load is stable. It can be used with AC servo motor or stepping motor to do any angle segmentation, which can not only meet the digital control that the divider cannot achieve, but also match the positioning accuracy of DD motor. It can greatly reduce the cost and bring you unexpected results.

It has the following characteristics:

1. Hollow structure

The rotary table of the hollow rotating platform is of hollow structure, and the servo motor is connected at the side, which is convenient for the installation of gas pipes and wires in the metallurgical tools.

2. High repetitive positioning accuracy

The hollow rotating platform adopts single-stage helical gear deceleration to increase the output torque, and the gear accuracy level is below level 5. In addition, the flexible gap adjustment mechanism controls the side clearance by changing the center distance of the two gears, so that the hollow rotating platform's air return is very small, and the repeated positioning accuracy is below 5 arc seconds.

3. High rigidity

The rotary table of the hollow rotating platform is supported by a set of precision cross roller bearings. The rollers in the bearings are arranged in a 90 degree staggered way, and the roller diameter is slightly larger than the raceway size between the inner ring and the outer ring of the bearing, so that there is a preload between the inner ring and the outer ring of the cross roller bearing and the rollers, so that the rotary table of the servo rotating platform supported by the bearings can bear various moments such as radial, axial and overturning, Its rigidity is more than 10 times that of traditional bearing.

4. High rotation accuracy

After the assembly of the servo rotating platform, the cross roller bearing of the platform is taken as the rotating center, and the outer diameter and end face of the rotary table are grinded again (the standard level is precision turning), so as to ensure the coaxiality and parallelism of the rotary table.

5. Any configuration of motor

The hollow rotating platform can flexibly change the size of the interface by customizing the flange and input shaft hole, which is suitable for connecting any brand of servo motor and stepping motor.

The hollow rotating platform is mainly used in CNC indexing device, manipulator joint, the fourth machining axis of machine tool, military radar, automatic production line and other rotating motion occasions with high precision and compact structure requirements.

Whether it is used as the fourth axis machining turntable of CNC machine, manipulator joint or as a part of manufacturing unit, the hollow rotating platform directly affects or even determines the machining accuracy and overall performance of its related products. The key to determine the performance of hollow rotating platform lies in the structure and accuracy of its supporting bearing type. No matter what kind of hollow rotating platform, its rotating support needs high positioning accuracy in axial and radial direction.

Cross roller bearing is also called cross roller bearing. Generally, cylindrical roller or tapered roller are used to cross arrange each other on a single raceway. The size section is small, and the distance between roller and roller is kept by retainer or spacer block. It has high rotation precision, large bearing capacity, small outline size, high rotation speed and rigidity, and it is very A wide range of uses.

In terms of structure, the structure of cross roller bearing is much simpler than that of traditional bearing. Through a single row of cross arranged cylindrical rolling elements, considerable axial and radial bearing capacity and overturning moment can be obtained. The structure is much simpler, while traditional bearings must be arranged in sequence through multiple sets of bearings to achieve the same effect, which brings about in design, assembly and installation Great convenience. Compared with the traditional bearings, the space occupied by the equipment is much smaller, and the assembly difficulty is also greatly reduced.

In terms of installation, the customized cross roller bearing is more convenient to install, the mechanism design is more simplified, and the installation hole design is added, the installation and use is more simple, greatly simplifying the structure of the rotating platform.

In terms of maintenance, the outer ring of cross roller bearing is designed with lubricating oil hole and oil groove, which is convenient for lubrication. Lithium based extreme pressure grease is used, which does not need to change grease frequently. It is a series of guarantees for bearing accuracy stability and life, which is conducive to delaying the friction and wear of bearing and extending the service life of bearing.

To sum up, the customized cross roller bearing has undoubtedly become an ideal choice for the rotating support bearing of hollow rotating platform.

Luoyang Hongyuan Bearing Technology Co., Ltd. can customize various types and requirements of cross roller bearings. We have conducted in-depth cooperation with many well-known manufacturers. Welcome to consult.